We decided last spring it was time to take down the above ground pool and put one in the ground. I had been planning to do an IG pool for 5 or 6 years. I had a local pool company give me a bid even though I was 90% sure I was going to do it myself. The bid was way high and they could not even start till October, so that was out the window. I ordered my pool kit from poolwarehouse on June 4th and due to COVID the shipping day was estimated to be 8+ weeks out. We decided on a 18x43x30 true L pool with a full width sun deck across the end of the L. The wait begins.

I had planned to build a pool house with a bathroom, kitchen, storage and outdoor kitchen to go along with the pool...so since the pool was going to be awhile, I started on the pool house. The pool house with porch was drawn up and I was ready to start. Ended up being 24x30 with 12' of the 30' being a covered porch.

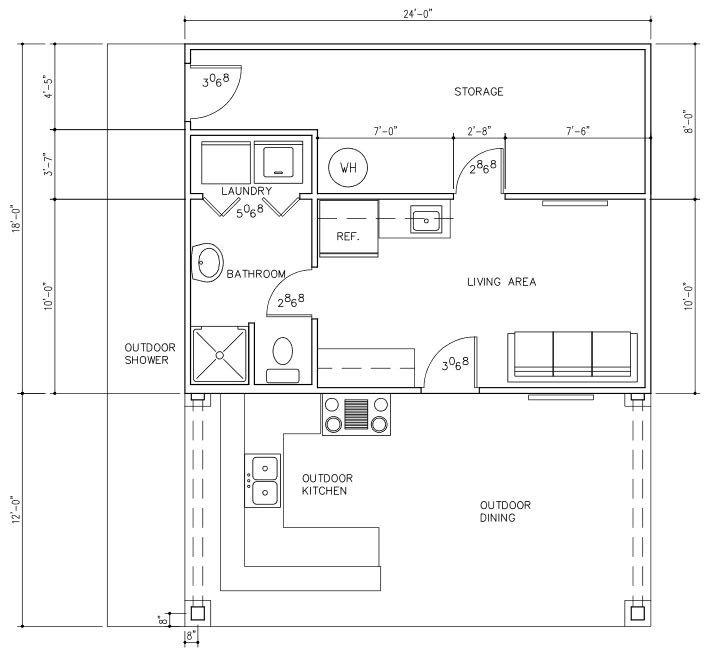

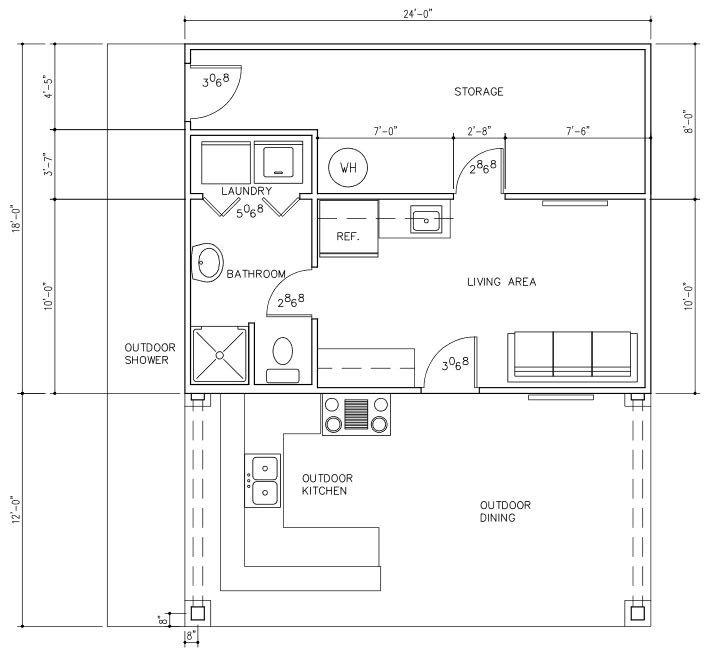

Here is the layout:

I figured out where I wanted the pool and pool house to be located and then figured the elevations on everything to match up to my existing patio. Once I knew the elevations I started building on the pool house.

I was making good progress on the pool house, almost had the outside finished and on August 24th my pool kit arrived. After doing an inventory, I was missing a few items related to the sun deck. It took about 2 weeks to get in the missing parts and another week to get a track hoe lined out to start the dig.

I took a week of vacation the day the dig started so I could get a good jump on it.

Day 1

I had planned to build a pool house with a bathroom, kitchen, storage and outdoor kitchen to go along with the pool...so since the pool was going to be awhile, I started on the pool house. The pool house with porch was drawn up and I was ready to start. Ended up being 24x30 with 12' of the 30' being a covered porch.

Here is the layout:

I figured out where I wanted the pool and pool house to be located and then figured the elevations on everything to match up to my existing patio. Once I knew the elevations I started building on the pool house.

I was making good progress on the pool house, almost had the outside finished and on August 24th my pool kit arrived. After doing an inventory, I was missing a few items related to the sun deck. It took about 2 weeks to get in the missing parts and another week to get a track hoe lined out to start the dig.

I took a week of vacation the day the dig started so I could get a good jump on it.

Day 1